By Paul Desmond, Managing Director of Leader Optec

Talk to data centre managers and the issue that keeps coming round is how to bolster their green credentials.

Data centres have been one of the biggest growth stories of the last ten years, mushrooming from virtually nothing to consuming anywhere between 3 and 5 per cent of the global electricity supply and accounting for around 2 per cent of total greenhouse gas emissions. This puts the data centre industry on a similar footing to the aviation industry.

In the US, research by the Natural Resources Defence Council recently claimed that 34 power plants, each generating 500 megawatts of electricity, are required to power today’s data centres. It predicts that by 2020 the number of power plants needed will have increased to over 50.

There will continue to be an exponential growth in the number of data centres from the very large ones run by the major Cloud providers to the tens of thousands of other centres supporting business and government.

The challenge is how to make them as energy efficient as possible and one of the key ways to achieve this goal is to make the networking infrastructure as effective as possible.

One important consideration is the amount of space that is required. A typical rack in a data centre used to consume under 2kW of power, but it is no longer acceptable to expect customers to continue ramping up the space they need in order to meet their rising power requirements.

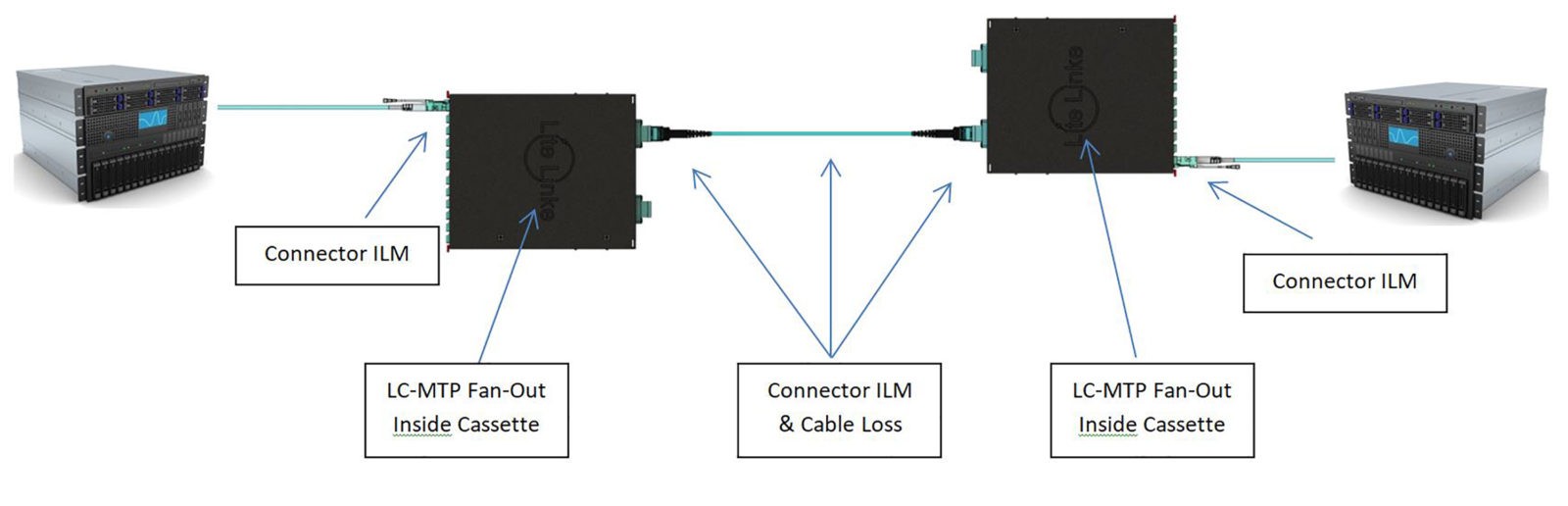

One trend is the increasing popularity of MTP technology over more conventional options. The adoption of MTP hyper high density modular design solutions can have a transformational impact on the efficiency of cabinet space with savings of up to 80 per cent. This translates into five times’ more fibre per cabinet.

While the space saving capability is one important consideration, there are a range of other key benefits in adopting MTP solutions.

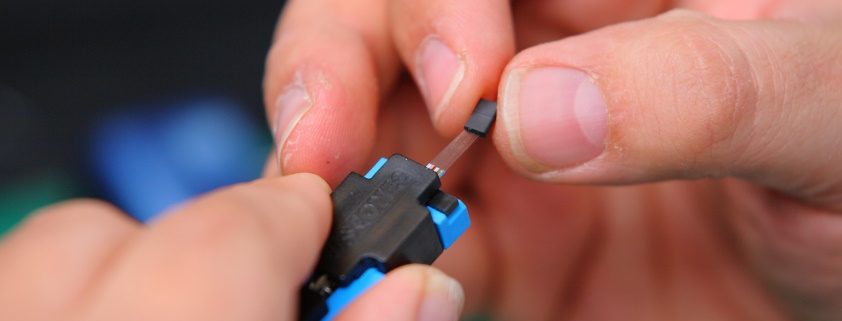

Speed is one such factor – the completely tool-less solution can achieve 24 connections in less than a minute compared to up to 40 minutes using a single fibre pre-termination. This can build to 144 fibres in a 1U configuration.

Alongside space and time savings is the cost saving. According to US Conec, every square metre of floor space costs US$ 45,000.

Innovation and flexibility are the key as data centres face the challenge of meeting the world’s storage requirements.

Today’s data centres and those that are in the planning need to do everything they can to ensure they are fully future-proofed and, at the same time, green. They need to be able to meet the voracious demands of the Cloud, Big Data, the Internet of Things and high performance computing.

This means embracing smart solutions to deliver the connectivity, power and cooling necessary.

How a data centre is networked is now high on the agenda to minimise the environmental impact of a facility’s infrastructure. Today’s data centre design centres on reducing wastefulness, something measured by Power Usage Effectiveness (PUE). Managers strive to see how close they can get to zero wasted energy.

No one is underestimating the challenges facing those with responsibility for the world’s data centres as well as their stakeholders who include the likes of Google, Facebook and Apple.

On the one hand, they are having to keep pace with the rapidly increasing bandwidth requirements of their customers – a big enough challenge in itself.

Alongside this they are expected to do everything they can to develop and protect their environmental credentials. Even organisations like Greenpeace recognise the size of the challenge facing the industry. Gary Cook, Greenpeace’s senior IT analyst, called it a “tremendous challenge”, adding: “If the sector simply grew on its current path without any thought as to where its energy came from, it would become a major contributor to climate change far beyond what it already is.”

Ian Bitterlin, one of the UK’s leading data centre experts and a visiting professor at the University of Leeds, says the amount of energy used by data centres is doubling every four years. Analysts are forecasting that data centres will consume roughly treble the amount of electricity over the next decade.

Leader Optec is also responding to a range of other challenges facing the sector. For example, we make a point of using recycled cable drums and work with some of our clients to collect and reuse their drums rather than allowing them to go to landfill.

As a company, we are also committed to recycling other products left after the installation process, and are currently working on the development of a wider initiative to help our customers and partners further reduce their carbon footprint.

The good news is that the industry is very much aware of the challenges it faces and strong collaboration between the various stakeholders will help to ensure that no stone is left unturned.

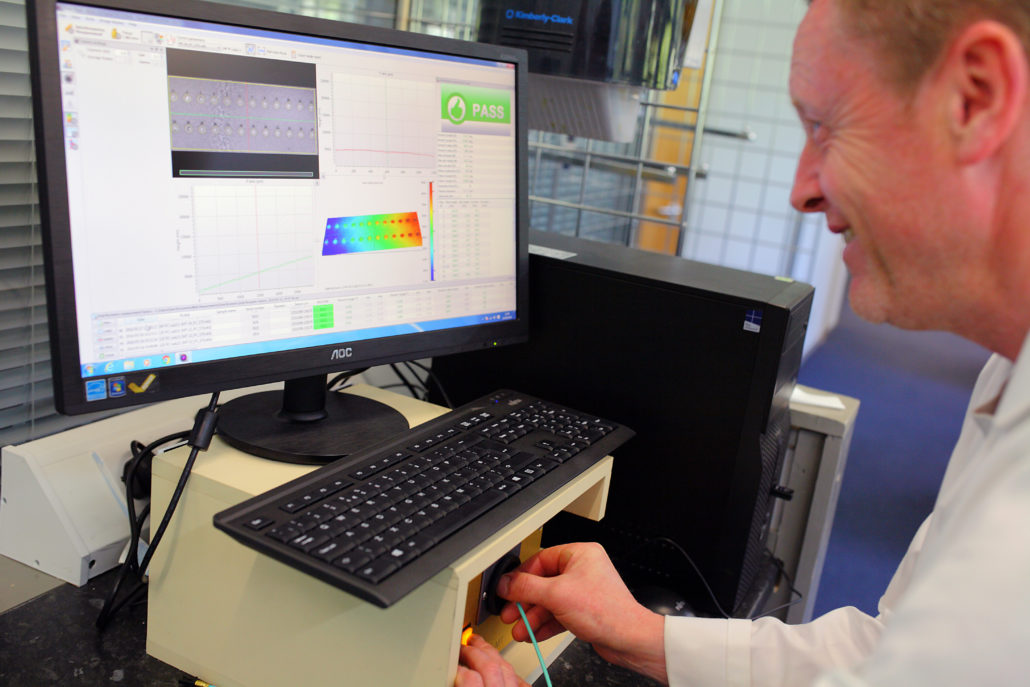

Paul Desmond is the Managing Director of Leader Optec. The company’s Lite Linke suite of MTP Elite Solutions utilises best-in-class components, bespoke design and UK manufacturing to meet the challenges facing networks.

All of the MTP connectivity, containment and cabling solutions are manufactured from Leader Optec’s headquarters in St Asaph. Products include cassettes and chassis as well as assemblies and accessories.